WH-30ES_PU_01

The AWTC WH-30ES is a premium 3-ton pallet truck with integrated digital weighing scale, engineered for demanding warehouse and logistics operations. Built with a reinforced steel frame and advanced load cell system, it enables both material handling and real-time weight measurement in one streamlined process.

Designed to reduce handling time and improve accuracy, the WH-30ES combines heavy-duty performance with smart weighing technology, making it an essential tool for environments where load verification is critical.

Key Features:

![]() Integrated Digital Scale: Features four internal load cells that provide accurate weight readings directly on the high-visibility LED display. The system supports multiple weighing functions, including tare, hold, accumulation, counting mode, and unit switching between kgand lb.

Integrated Digital Scale: Features four internal load cells that provide accurate weight readings directly on the high-visibility LED display. The system supports multiple weighing functions, including tare, hold, accumulation, counting mode, and unit switching between kgand lb.

![]() 3 Ton Load Capacity: Built for industrial applications, the WH-30ES handles up to 3000 kg without compromising on maneuverability or safety.

3 Ton Load Capacity: Built for industrial applications, the WH-30ES handles up to 3000 kg without compromising on maneuverability or safety.

![]() Optimized Fork Dimensions:

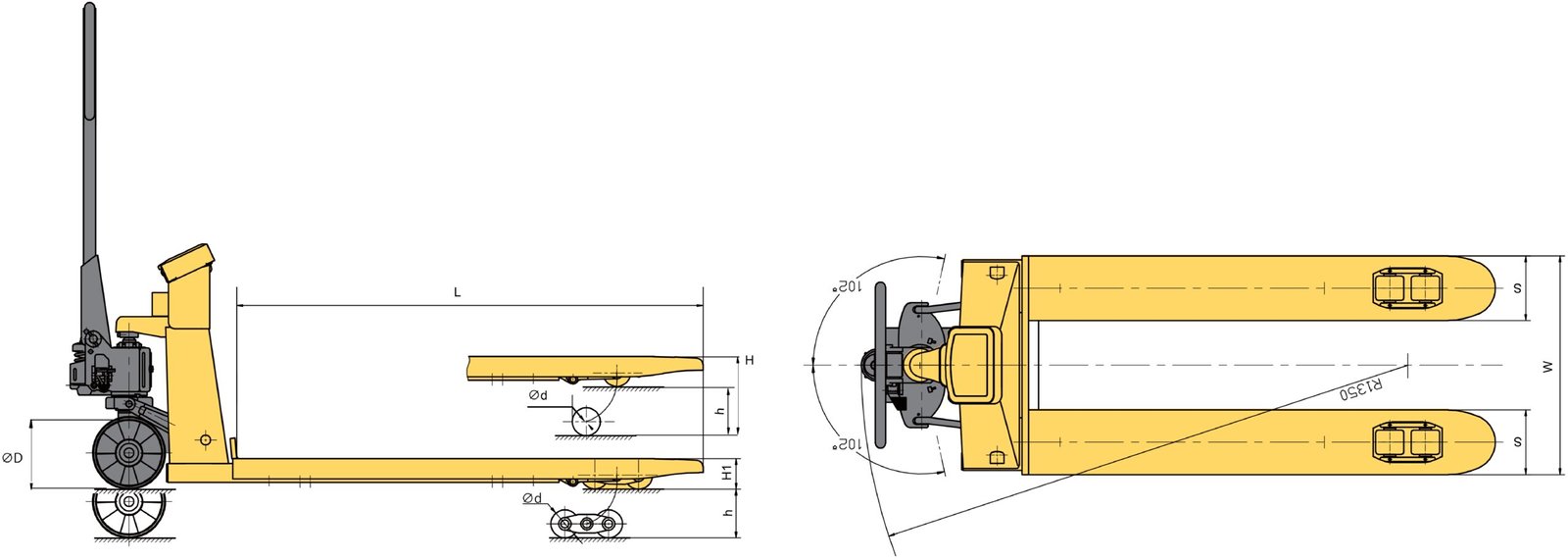

Optimized Fork Dimensions:

![]() Heavy duty pallet truck: Designed for standard pallets with a fork width of 540mm, ensuring compatibility across most warehouse systems.

Heavy duty pallet truck: Designed for standard pallets with a fork width of 540mm, ensuring compatibility across most warehouse systems.

![]() Low Profile Entry: With a lowered fork height of 78mm, it offers smooth entry and exit from low-clearance pallets, minimizing strain and damage.

Low Profile Entry: With a lowered fork height of 78mm, it offers smooth entry and exit from low-clearance pallets, minimizing strain and damage.

![]() PU Wheels for Smooth Operation: Equipped with durable polyurethane (PU) wheels that provide quiet, floor-protective movement, ideal for indoor use on various surfaces.

PU Wheels for Smooth Operation: Equipped with durable polyurethane (PU) wheels that provide quiet, floor-protective movement, ideal for indoor use on various surfaces.

![]() Long Battery Life: Powered by a rechargeable internal battery system, the unit delivers extended usage without frequent recharging, supporting continuous warehouse operations.

Long Battery Life: Powered by a rechargeable internal battery system, the unit delivers extended usage without frequent recharging, supporting continuous warehouse operations.

![]() Industrial Durability: Built with 4mm thick steel forks and a cast galvanized pump, ensuring longevity and resistance under harsh working conditions.

Industrial Durability: Built with 4mm thick steel forks and a cast galvanized pump, ensuring longevity and resistance under harsh working conditions.

Applications:

The AWTC WH-30ES pallet truck is ideal for:

![]() Warehouses and distribution centers requiring both transport and weighing functionality.

Warehouses and distribution centers requiring both transport and weighing functionality.

![]() Shipping and receiving docks where load verification is essential.

Shipping and receiving docks where load verification is essential.

![]() Manufacturing units managing bulk materials and inventory by weight.

Manufacturing units managing bulk materials and inventory by weight.

![]() Quality control environments where weight compliance must be recorded.

Quality control environments where weight compliance must be recorded.

![]() Operations looking to reduce handling steps and improve workflow accuracy.

Operations looking to reduce handling steps and improve workflow accuracy.

This model is particularly valuable in industries where weight precision directly affects cost, documentation, or compliance, such as food distribution, packaging, retail warehousing, and production environments.

| Feature | |||

|---|---|---|---|

| 1.1 | Capacity | kg | 3000 |

| 1.2 | Pump type | Integrated | |

| 1.3 | Accuracy | % | ±0.5 |

| Wheel | |||

| 2.1 | Wheel (drive/load) Type | PU | |

| 2.2 | Size of steering wheel | ΦD (mm) | 180*50 |

| 2.3 | Size of loading wheel (single) | Φd (mm) | 70*96 |

| 2.4 | Size of loading wheel (double) | Φd (mm) | 70*70 |

| Dimensions | |||

| 3.1 | Lifting height | H (mm) | 120 |

| 3.2 | Max. fork lifting height | h (mm) | 198 |

| 3.3 | Lowered height of fork | H1 (mm) | 78 |

| 3.4 | Fork outside distance | W (mm) | 540 |

| 3.5 | Fork length | L (mm) | 1150 |

| 3.6 | Fork width | S (mm) | 160 |

| 3.7 | Weight | kg | 98–108.5 |

| Battery | |||

| 4.1 | Battery voltage | V | 6 |

| 4.2 | Battery capacity | Ah | 4 |

| Remark | Standard | ||